Casket for engagement ring

Background

At first I thought about making the engagement ring myself, but unfortunately I don’t own any goldsmith tools. Instead of the normal packaging of a ring from a jeweller, I wanted to make a very personal casket instead.

Material

The box consists of two types of wood, oak and bongossi (Lophira alata).

The oak was once a village oak in the center of a village north of Dresden, until it had to be felled in the 1960s because of a pest infestation. This oak was then sawn into planks. Some of these planks were used immediately, others were stored in a dry and shady barn until 2015. Due to this extremely long, optimal storage, the wood is perfectly dried and has reached the highest quality.

The Bongossi wood was felled much earlier – in a Dutch colony when the Netherlands still had colonies. This wood is at least 250-300 years old and was used as a deck on 3-4 generations of dutch barges before it ended up in the port of Amsterdam. In the 1990s friends of mine bought this wood to use as a ship deck. I was allowed to take some short sections of this incredible wood with me.

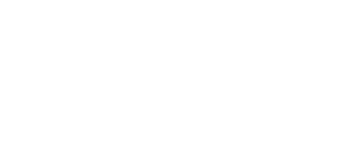

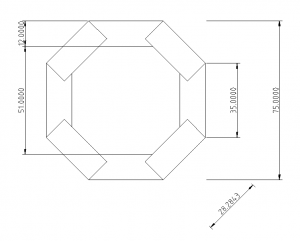

Body

The body of the casket is composed of individual strips. The English term for this wood joint is a birdsmouth joint. I have no idea what the correct German term for this wood joint would be.

If you know what the correct German term is, please send me an e-mail.

The initially still rectangular strips I brought with the self-made tiltable router lift into the form that 8 pieces of it, alternately used, form the tubular basic form of the body. I cut the birdsmouths into the oak and not into the bongossi, because the oak, although very hard, is much easier to process than the even harder bongossi.

The bottom of the body consists of a thin board of oak wood, which is simply glued on.

Lid

The lid consists of a segment of the tube, as does the body of the casket. To keep the lid closed tighter, I have made a lip. For this I removed about 6mm from the outside of the body, then I removed a little more than 6mm from the inside of the lid.

For the body I used the router, in the lid this was not possible, here I could remove only a partial amount with the router, the rest was removed with a chisel.

On top of the ring segment I glued a thin board of bongossi to close the lid. I made this thin board by gluing single strips together.

By using oak as the base and bongossi as the lid, I tried to incorporate the alternating colours of the tube.

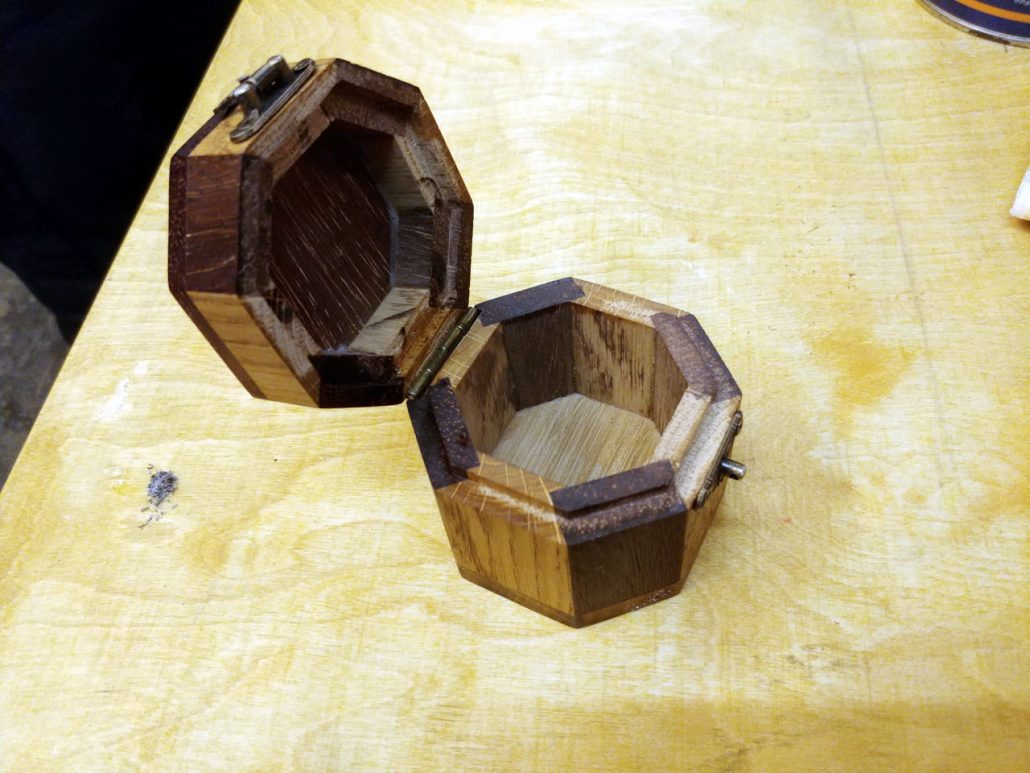

Inlays / Signet

The lid should be decorated with something personal. I decided to use inlays here. However, I did not produce these inlays traditionally, but used the CNC milling machine.

No rectangular particles of wood are used in this process, but wedge-shaped ones. Both sides are cut out with a V-shaped cutter and can then be glued together. After the glue has dried, the wood that has been used is sawn off. However, it is absolutely necessary to leave 1-2 mm of material, which is then carefully removed with a sanding machine. One must carefully approach the perfect picture, in order not to remove too much.

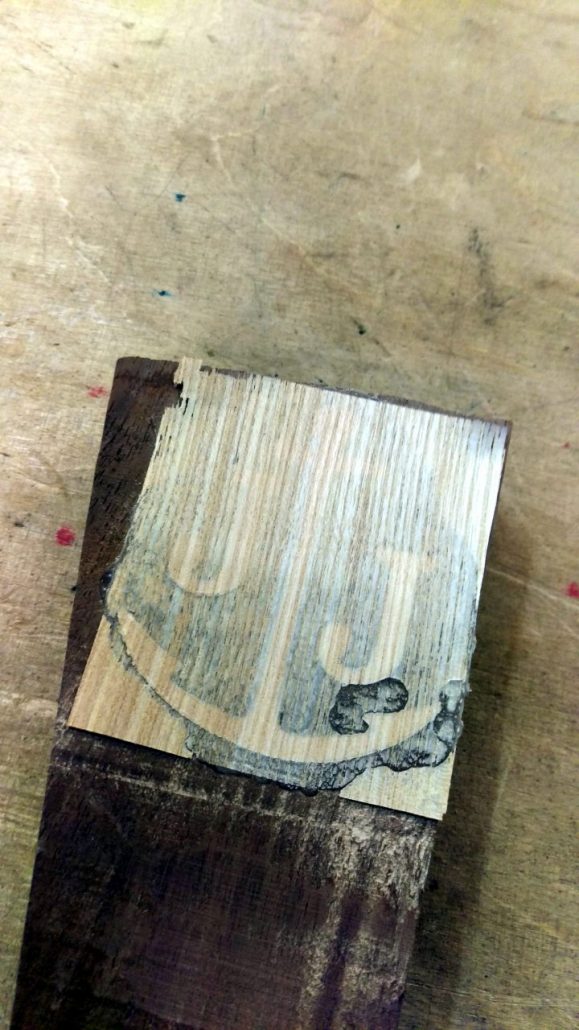

After milling of v-shaped inlays

While glueing both parts

After cutting of the wood, during sanding

Nearly there

Different try, this one with final Signet, Wood is Cheery and Oak

I needed several attempts until I had the process worked out well enough that I wanted to mill something on the half-finished casket, which had already received a lot of work.

The symbol that forms the inlay is based on elements from the ex Libris of my father’s family and the initials of me and my fiancée.

We will continue to use this logo in the future, e.g. to mark property, or as an old-fashioned seal.

Engagment

I presented the box with the ring during a dinner in a gourmet restaurant on the island of Usedom.

She said YES!