engraved Zippos for the c-base-Crew

Background

In November 2024 I started working on the idea of engraving Zippo lighters myself. As a regular Zippo user, I was intrigued by the possibility of customizing the surface. I knew from the outset that this would require precise data and a dedicated fixture. Using a touch probe, I measured the curvature of a Zippo and reconstructed a set of geometric data, which then served as the basis for designing a clamping fixture.

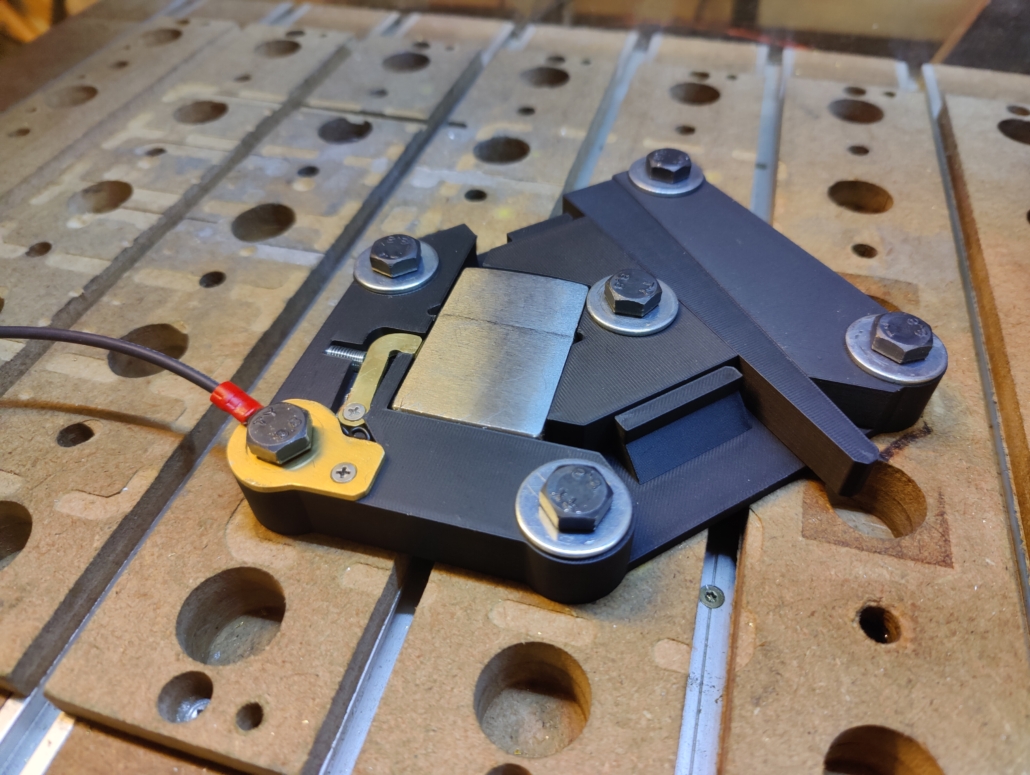

Fixture

The fixture consists of three parts: a base, a clamp, and a wedge. The Zippo is held between the base and the clamp, while the wedge presses them together to create a stable fixation. I also integrated an electrical contact into the base, made from two CNC-milled brass components. The first is a spring-loaded contact that presses against the surface of the Zippo and provides a precise electrical reference for height probing. The second serves as a solid mounting point for the cable connection, linking the contact electrically to the rest of the machine. This setup allowed me to determine the vertical zero point before each engraving and ensured that the engraving tip neither cut too deep nor too shallow.

Tool selection

My initial attempts used rotating engraving bits with angles between 20 and 60 degrees. I tested them on scrap brass to evaluate the method. The results, however, were disappointing. The engravings appeared rough, uneven, and visually unsatisfying. After several weeks I put the project aside. Half a year later I came across a spring-loaded carbide engraving stylus that does not rotate but is instead dragged across the surface by the machine. Rather than cutting, it scratches fine lines directly into the brass. This approach turned out to be precise, consistent, and visually convincing.

small series production

With the new tool I was finally able to complete the project. I ordered thirty Zippos and engraved them using this technique. The finished lighters were passed on to members of the c-base crew at cost price. To make the process transparent, I produced a video showing the use of the fixture, the engraving itself, and the final results.

Conclusion

Working on the Zippos was marked by many failed attempts and a long detour before I found the right solution. Only the combination of a precise fixture and the spring-loaded engraving stylus made it possible to achieve the fine lines I had envisioned.