Compressed air system at c-base

Background

On board the c-base space station there had so far been no central compressed air supply. Yet it would be useful for a variety of purposes. The laser cutter in the c-lab would benefit from air assist, the drill press and CNC mill could be equipped with minimal quantity lubrication, and the scroll saw could profit from chip extraction. Compressed air would also be helpful in outdoor areas such as the courtyard or the riverside strip, for example for grinding work or inflating tires.

Planning

First I determined in detail which components would be necessary for an initial expansion stage. I produced sketches of the piping routes and compiled parts lists in which every connector, every meter of hose, and each valve, pressure regulator or mounting element was recorded. On this basis I calculated the costs. Only then did I submit an application to the association to provide the required funds. The compressor accounted for a sum of around 500 euros. Hoses, connectors and mounting materials added up to a similar amount. I chose a compressor of the Stahlwerk brand with a 50-liter tank and a maximum pressure of 10 bar, as these models are particularly quiet.

Implementation

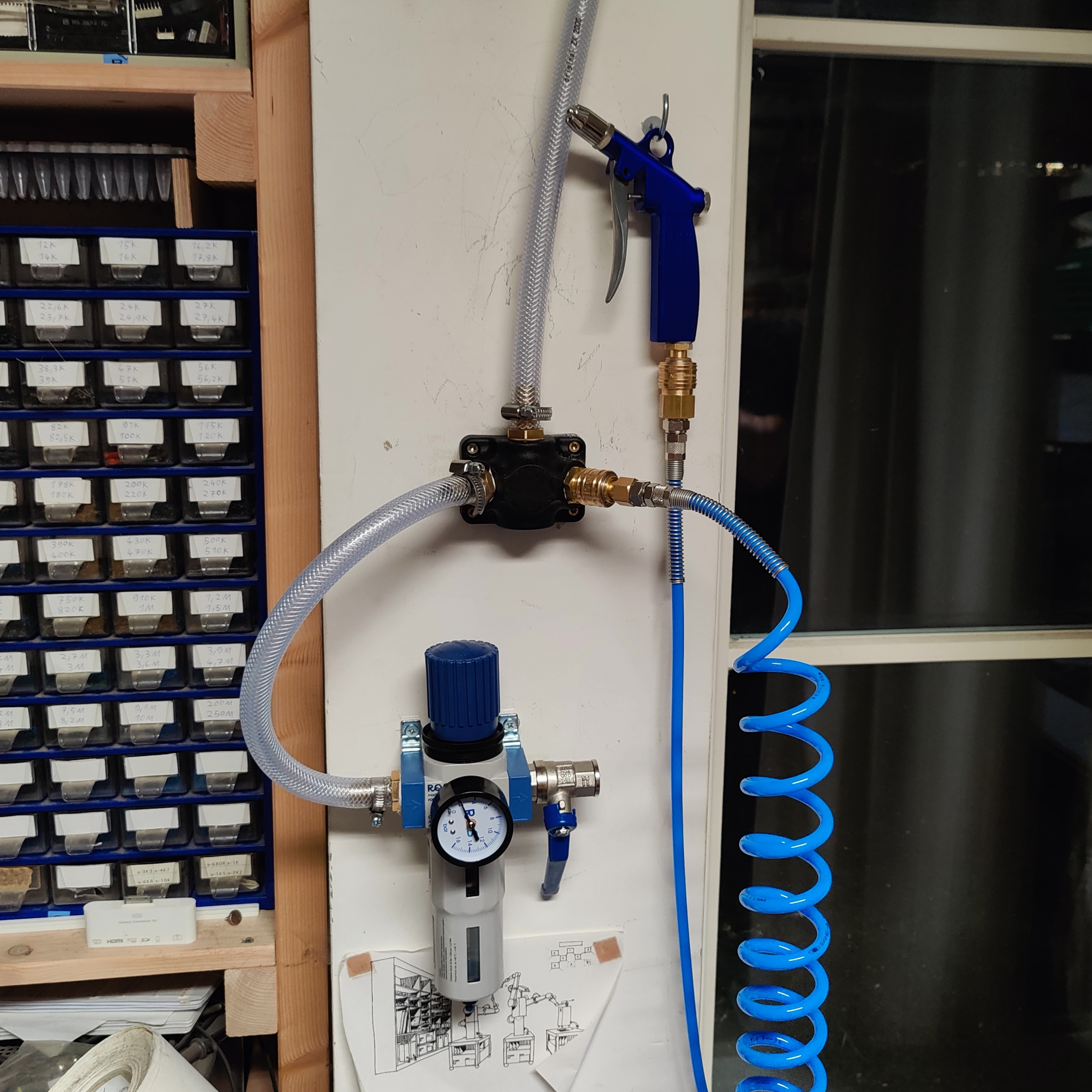

In the first step, with the help of many members, I installed the compressed air lines on the lower floor. The c-lab received its own connection for the laser cutter, supplemented by a pressure regulator and an additional air filter with a wall outlet. This allows devices to be blown out without fine particles or oil residues causing problems. In the workshop I laid permanent connections to three machines. The CNC mill, drill press and scroll saw are operated through a pressure regulator that reduces the working pressure to values between 1 and 2.5 bar, depending on requirements. I also installed several wall connections where mobile tools can be operated at full pressure.

The compressor was placed in a corner of the hardware storage area, where its noise is least disturbing. The central compressed air distribution to the various rooms is also located there.

For the outdoor area I set up two connections. One is located in the courtyard, another next to the emergency exit door at the riverside strip. This makes compressed air available outside as well, for example for grinding or for simple tasks such as inflating tires.

Several members of the c-base e.V. helped with these installation works.

In this expansion stage I used simple hose clamps. This solution was quickly available but turned out not to be optimal, since it is not easy to achieve a tight seal without overtightening the threads. I was repeatedly advised to use double-ear hose clamps, which are said to be better suited for permanent installations. For the further expansion of the compressed air network on the upper floor I will try these out.

Result

The c-base now has a functioning compressed air installation on the lower floor. In the c-lab the laser cutter is connected, in the workshop three machines are supplied with regulated low pressure, and there are wall outlets for tools. In the outdoor area two additional connections are available. The installation was financed by the c-base e.V., in whose premises it is located.