Wooden Tablesaw

Tasks and requirements

Tasks and requirements

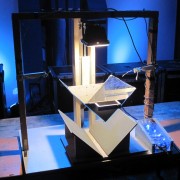

The construction of the Vacuum Forming Machine was the goal of this project. For this construction, many 18mm thick boards had to be cut to length and appropriate width. The use of a circular saw would have been possible, but impractical. Because of this demand, the decision was made to construct a table saw.

mechanical Base

As starting point for the construction I bought a used small table saw for amateurs and hobbyists, which dimensions were not sufficient. Furthermore, this table saw lacked the grooves for use of movable cross cut fences and a proper rip cut fence. The rip saw fence of this table saw was, as expected, unusable.

Extensions and conversions

All add-on parts of the table saw were removed, the table saw was dismantled and all parts with too much play were adjusted accordingly, oiled, cleaned and reassembled. The electrical wiring was thoroughly checked and did not need any repairs.

Then I designed a new table for the saw, which is both longer and wider than the old table. This table was stiffened with a profile cut from seasoned german Ashwood. On this profile, the mounting bracket made of birch plywood for the rip cut fence runs. Birch plywood was used because, although it counts as a hardwood, it is slightly softer than the ash and therefore the Ash parts can not produce divets in the ash profile. Exclusively straight grown ash was used because of the low seasonal deformation and dimensional stability, as well as the hardness of this European hardwood. Both the cross cut fence and the rip fence were made from ash wood.

Because of the low friction coefficient a plywood veneer from beech was used for the surface of the table. The substructure of the table is made of pine slats. Since neither the seasonal expansion nor the hardness of the wood were relevant here, I could resort to the cheapest type of wood.

Success

The project was successful, the vacuum forming machine, and some other projects were built with this improvised table saw. The cost of this construction were paid by the c-base e.V. Through good contacts with some furniture makers some of the hardwood parts were given to us for free.

Update August 2015

The table saw has been exchanged for a large part of the necessary components for a CNC milling machine. This was possible because the new table saw is finished and ready for use, and the old table saw has therefore become redundant. This table saw now lives in the shop of tecdroid