Inlays with the CNC milling machine

Background

The initials of my good friend Suski’s parents’ first names are both the letter T. For 35 years, their parents have been using a symbol for all sorts of things, which consists of two Ts forming a heart. The idea of the project was to put an inlay into a smaller piece of wood and to give this as an unfinished project to the parents, because her father, who is a skilled craftsman, will certainly be happy to make something beautiful from it.

Project

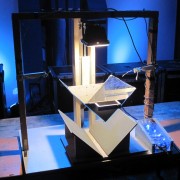

Because the symbol was never digitized, it only existed in Suski’s memory, we worked several hours with the openSource vector graphics program “Inkscape” until we found a form that corresponded exactly to Suski’s memory. In the precious wood waste box we found a piece of Californian walnut, as well as a rest of the living room lamp made of wild cherry.(the core I broke out to make room for the electrical wiring)

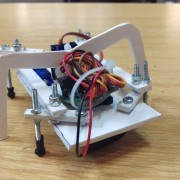

With the free software F-Engrave we created the machine path for our self-made CNC milling machine. This software is specialized in a process called “V-Carving”, in which a V-shaped cutter removes material and creates V-shaped grooves. Due to the vertical position and the V-shape, the apparent diameter of the cutter is freely variable so that very narrow structures and pointed corners can be produced.

This software also allows to create a machine path for the positive, the actual inlay. Since there is considerably more material to be removed here than with the negative, the software allows the machining to be carried out in several steps and with different tools, whereby a large part of the material is removed with a cylindrical cutter.

After milling, both parts were glued with wood glue and pressed together well. After the glue had cured completely, we sawed both parts apart and then ground the workpiece to a smooth finish before it was oiled with a hard wax.

Sucess

Unfortunately, a small corner of the positive has been broken off during milling (top of the heart, on the right T), except for this small flaw, the project has been successful and we are satisfied with the result. The last remaining question for me is what Suski’s father will do with this started project, I am curious.

Video

I accompanied this project with the camera as well: