Programming of a coil winding machine

Background

B + B Wickeltechnik GmbH develops special coils for chokes and transformers. For a new customer, this company needs a machine that winds a special transformer coil that delivers 5000V on the secondary side. The company created a prototype of this machine for a lab environment and approached me with the request to program the prototype and put it into operation.

Implementation

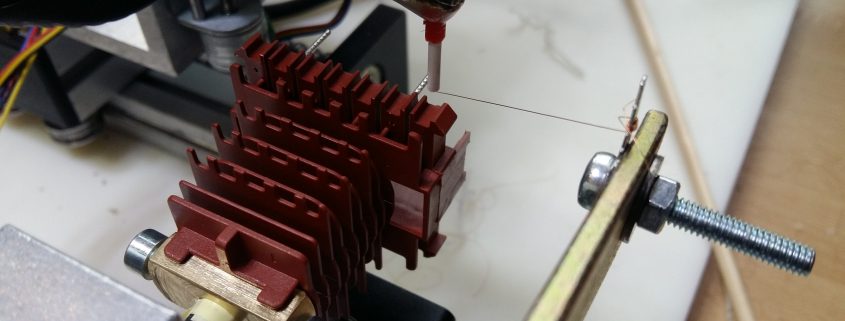

After I was booked, I went to this company and looked at the machine. The system consists of four CNC-controlled axes, the wire guide is movable in two axes (vertical, Z and horizontal, X, top of the image). The coil is linearly movable, parallel to the axis of rotation (Y, right in the picture) and the coil can be rotated CNC-controlled (A)

After I was booked, I went to this company and looked at the machine. The system consists of four CNC-controlled axes, the wire guide is movable in two axes (vertical, Z and horizontal, X, top of the image). The coil is linearly movable, parallel to the axis of rotation (Y, right in the picture) and the coil can be rotated CNC-controlled (A)

It is important that the winding wire is attached to an auxiliary pin before the start of each cycle so that the wire can be guided in a controlled manner. This auxiliary pin had yet to be assembled, here I tried various positions and ultimately constructed a solution ad hoc from existing materials.

The component itself consists of two coils, the primary winding and the secondary winding. Within the scope of this project, only the secondary winding should be done. The secondary winding is spread out over six individual chambers. Before the winding was started, the wire had to be fastened to the first pin (input) of the secondary winding, after the end of the winding, the wire had to be fastened to the second contact pin (output). The wire was applied to the pins by wrapping it around several times without soldering or gluing. The very thin wire (0.07mm) is attached there exclusively by friction and a bit of tension, which the wire guide maintains.

My tasks were to program the machine control for this process. The program Mach3 of the company ArtSoft is used for machine control. The procedure was programmed by me using G-Code.

Success

During the final stages of the project, mechanical problems with the Z-axis came to light which prevented a productive operation for the time being, but the principle and the general feasibility of this type of construction could be successfully demonstrated and the B + B Wickeltechnik is satisfied with my work.